Level sensors

detect the level of liquids and other fluids and fluidized solids, including slurries, granular materials, and powders that exhibit an upper free surface. Substances that flow become essentially horizontal in their containers (or other physical boundaries) because of gravity whereas most bulk solids pile at an angle of repose to a peak. The substance to be measured can be inside a container or can be in its natural form (e.g., a river or a lake). The level measurement can be either continuous or point values. Continuous level sensors measure level within a specified range and determine the exact amount of substance in a certain place, while point-level sensors only indicate whether the substance is above or below the sensing point. Generally, the latter detect levels that are excessively high or low.

There are many physical and application variables that affect the selection of the optimal level monitoring method for industrial and commercial processes. The selection criteria include the physical: phase (liquid, solid or slurry), temperature, pressure or vacuum, chemistry, dielectric constant of medium, density (specific gravity) of medium, agitation (action), acoustical or electrical noise, vibration, mechanical shock, tank or bin size and shape. Also important are the application constraints: price, accuracy, appearance, response rate, ease of calibration or programming, physical size and mounting of the instrument, monitoring or control of continuous or discrete (point) levels. In short, level sensors are one of the very important sensors and play very important role in a variety of consumer/ industrial applications. As with other types of sensors, level sensors are available or can be designed using a variety of sensing principles. Selection of an appropriate type of sensor suiting to the application requirement is very important.

But is there need for such technology—or any level sensing device is the question that many people may ask. However, with the competitive nature of the industry and the consistently wanting to improve quality, reduce costs, inefficiencies and waste kind of mentality, no company wants to take the risk at offering solutions that are not performing as best as they could be.

- Optical

- Vibrating or tuning fork

- Ultrasonic

- Float

- Capacitance

- Radar

- Conductivity or resistance

Magnetic and mechanical float

The principle behind magnetic, mechanical, cable, and other float level sensors often involves the opening or closing of a mechanical switch, either through direct contact with the switch, or magnetic operation of a reed. In other instances, such as magneto strictive sensors, continuous monitoring is possible using a float principle.

With magnetically actuated float sensors, switching occurs when a permanent magnet sealed inside a float rises or falls to the actuation level. With a mechanically actuated float, switching occurs as a result of the movement of a float against a miniature (micro) switch. For both magnetic and mechanical float level sensors, chemical compatibility, temperature, specific gravity (density), buoyancy, and viscosity affect the selection of the stem and the float. For example, larger floats may be used with liquids with specific gravities as low as 0.5 while still maintaining buoyancy. The choice of float material is also influenced by temperature-induced changes in specific gravity and viscosity – changes that directly affect buoyancy.

With magnetically actuated float sensors, switching occurs when a permanent magnet sealed inside a float rises or falls to the actuation level. With a mechanically actuated float, switching occurs as a result of the movement of a float against a miniature (micro) switch. For both magnetic and mechanical float level sensors, chemical compatibility, temperature, specific gravity (density), buoyancy, and viscosity affect the selection of the stem and the float. For example, larger floats may be used with liquids with specific gravities as low as 0.5 while still maintaining buoyancy. The choice of float material is also influenced by temperature-induced changes in specific gravity and viscosity – changes that directly affect buoyancy.

Float-type sensors can be designed so that a shield protects the float itself from turbulence and wave motion. Float sensors operate well in a wide variety of liquids, including corrosives. When used for organic solvents, however, one will need to verify that these liquids are chemically compatible with the materials used to construct the sensor. Float-style sensors should not be used with high viscosity (thick) liquids, sludge or liquids that adhere to the stem or floats, or materials that contain contaminants such as metal chips; other sensing technologies are better suited for these applications.

Conductive

Conductive level sensors are ideal for the point level detection of a wide range of conductive liquids such as water and is especially well suited for highly corrosive liquids such as caustic soda, hydrochloric acid, nitric acid, ferric chloride, and similar liquids. For those conductive liquids that are corrosive, the sensor’s electrodes need to be constructed from titanium, Hastelloy B or C, or 316 stainless steel and insulated with spacers, separators or holders of ceramic, polyethylene and Teflon-based materials. Depending on their design, multiple electrodes of differing lengths can be used with one holder. Since corrosive liquids become more aggressive as temperature and pressure increase, these extreme conditions need to be considered when specifying these sensors.

Conductive level sensors are ideal for the point level detection of a wide range of conductive liquids such as water and is especially well suited for highly corrosive liquids such as caustic soda, hydrochloric acid, nitric acid, ferric chloride, and similar liquids. For those conductive liquids that are corrosive, the sensor’s electrodes need to be constructed from titanium, Hastelloy B or C, or 316 stainless steel and insulated with spacers, separators or holders of ceramic, polyethylene and Teflon-based materials. Depending on their design, multiple electrodes of differing lengths can be used with one holder. Since corrosive liquids become more aggressive as temperature and pressure increase, these extreme conditions need to be considered when specifying these sensors.

Conductive level sensors use a low-voltage, current-limited power source applied across separate electrodes. The power supply is matched to the conductivity of the liquid, with higher voltage versions designed to operate in less conductive (higher resistance) mediums. The power source frequently incorporates some aspect of control, such as high-low or alternating pump control. A conductive liquid contacting both the longest probe (common) and a shorter probe (return) completes a conductive circuit. Conductive sensors are extremely safe because they use low voltages and currents. Since the current and voltage used is inherently small, for personal safety reasons, the technique is also capable of being made “Intrinsically Safe” to meet international standards for hazardous locations. Conductive probes have the additional benefit of being solid-state devices and are very simple to install and use. In some liquids and applications, maintenance can be an issue. The probe must continue to be conductive. If buildup insulates the probe from the medium, it will stop working properly. A simple inspection of the probe will require an ohmmeter connected across the suspect probe and the ground reference.

Conductive level sensors use a low-voltage, current-limited power source applied across separate electrodes. The power supply is matched to the conductivity of the liquid, with higher voltage versions designed to operate in less conductive (higher resistance) mediums. The power source frequently incorporates some aspect of control, such as high-low or alternating pump control. A conductive liquid contacting both the longest probe (common) and a shorter probe (return) completes a conductive circuit. Conductive sensors are extremely safe because they use low voltages and currents. Since the current and voltage used is inherently small, for personal safety reasons, the technique is also capable of being made “Intrinsically Safe” to meet international standards for hazardous locations. Conductive probes have the additional benefit of being solid-state devices and are very simple to install and use. In some liquids and applications, maintenance can be an issue. The probe must continue to be conductive. If buildup insulates the probe from the medium, it will stop working properly. A simple inspection of the probe will require an ohmmeter connected across the suspect probe and the ground reference.

Typically, in most water and wastewater wells, the well itself with its ladders, pumps and other metal installations, provides a ground return. However, in chemical tanks, and other non-grounded wells, the installer must supply a ground return, typically an earth rod.

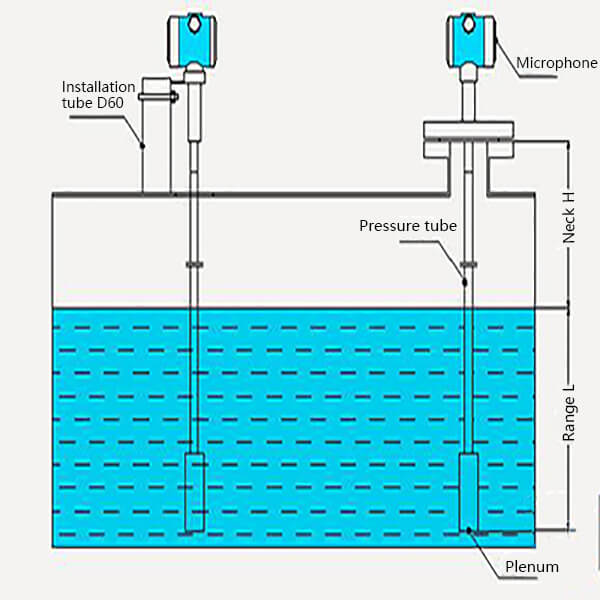

Ultrasonic Level

![]()

Feature

- It is possible to be used in the liquid level of degree of fixation.

- The installation is simple and it is possible to adjust the on-off switch freely on-site.

- It is widely used in the sewage treatment plants and water tanks

- The corrosiveness is strong

- Since it is possible to have a 2line type, the wiring work is simple and the construction cost can be saved.

- It is possible to consecutively control the motors as many as wanted

Applications

- It is widely used for water tanks and tanks with high corrosiveness

- It is widely used for tanks for drainage.

- It is widely used for wastewater tanks

- It is used in diverse water tanks