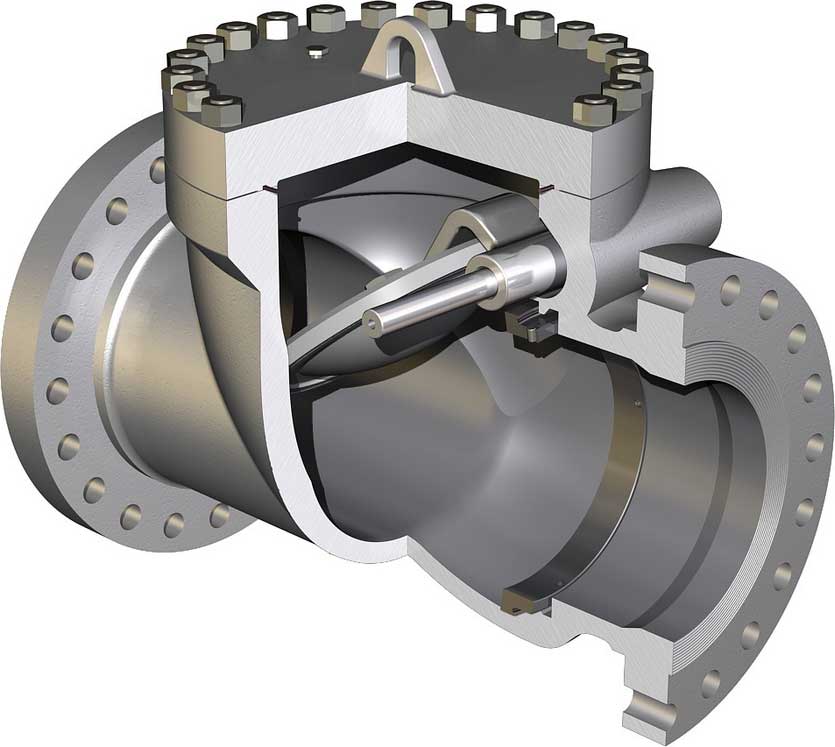

Check valve is a one-way valve allowing fluid to flow through one opening and leave through the other.

The general purpose of this valve is to prevent backflow (flow in the opposite direction).

Check valves inherit the term “cracking pressure”. When the cracking pressure is reached, the valve will open. When the pressure drops below the cracking pressure and/or back-pressure occurs, the valve closes. The way a Check valve operates is ideal for preventing contamination from fluid flowing into separate services connected to a common header. This valve works automatically, and typically with no human or external control, such as a valve handle or stem.

Check valves have different configurations with the most common being the swing, tilting-disc, wafer, lift, and stop-check valves.

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Check valves are two-port valves, meaning they have two openings in the body, one for fluid to enter and the other for fluid to leave. There are various types of check valves used in a wide variety of applications. Check valves are often part of common household items. Although they are available in a wide range of sizes and costs, check valves generally are very small, simple, and inexpensive. Check valves work automatically, and most are not controlled by a person or any external control; accordingly, most do not have any valve handle or stem. The bodies (external shells) of most check valves are made of plastic or metal.

An important concept in check valves is the cracking pressure which is the minimum differential upstream pressure between inlet and outlet at which the valve will operate. Typically, the check valve is designed for and can therefore be specified for a specific cracking pressure.

Ball Valve, Segmented Valve, Dome  Valve, V Port Ball Valve, Plug Valve

Valve, V Port Ball Valve, Plug Valve

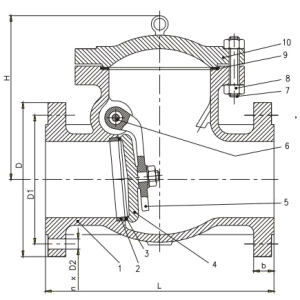

Constructive and functional characteristics

- type: bolted cover

- flanged ends

- mounting position: horizontal, taking care of the flowing direction indicated by arrow

- free stroke

- other shell materials (Carbon steel, Stainless steel, Monel, Duplex, Inconel)

- other trim

- other flange facings according to ANSI B 16.5 or B/W ends to ANSI B16.25

- other type gasket body – bonnet

- lantern ring for class 300

- drain tappings

- by-pass

- manufactured according to specification NACE MR 0175 for hydrogen sulphide and sour gas service